The motor drives the eccentric shaft to rotate by the V-belt & the slot wheel, then the movable jaw moves back and forth to break the materials in the crushing cavity which is composed of fixed jaw plate & movable jaw plate and side guard plate. When the movable jaw rises, the angle between the fixed jaw and movable jaw gets larger, and the materials can be broken to reach the crushing target. When the movable jaw is moving down, the angle between the fixed jaw and movable jaw becomes smaller .the end products slide from the discharge opening at the bottom.

---Application

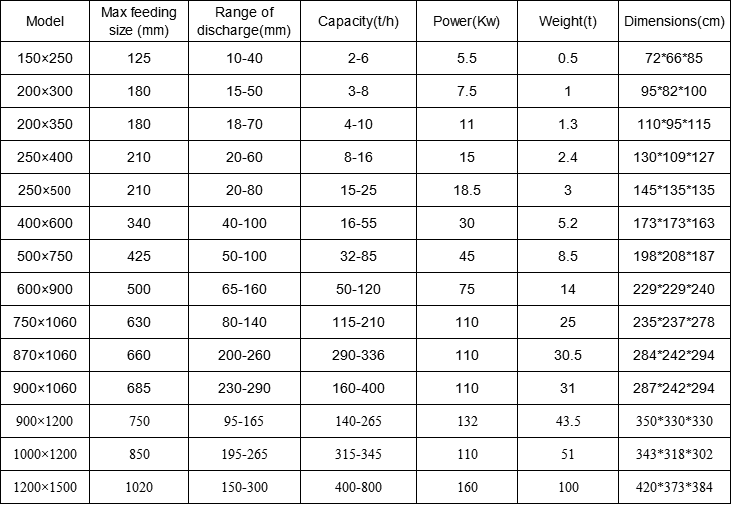

Jaw crusher is be widely applied in metallurgic, mining, chemical, cement, construction, refractory and ceramics industries, for the medium or fine crushing of various

medium hard rocks and minerals, etc. The jaw crusher is capable to crush mineral ores, rocks, and slag with crush strength less than 280Mpa. And size of materials fed in the stone jaw crusher should be equal or smaller than the maximum feeding size described in the following technical data.

1.Big reduction ratio

2.Even granularity

3.Simple structure

4.Reliable working condition

5.Convenient repair and economic operation

6.Widely used for mine, smelting, building material, road, railway, irrigation works

Chemical and materials with compression strength no more than 320 Mpa.

---Product pictures