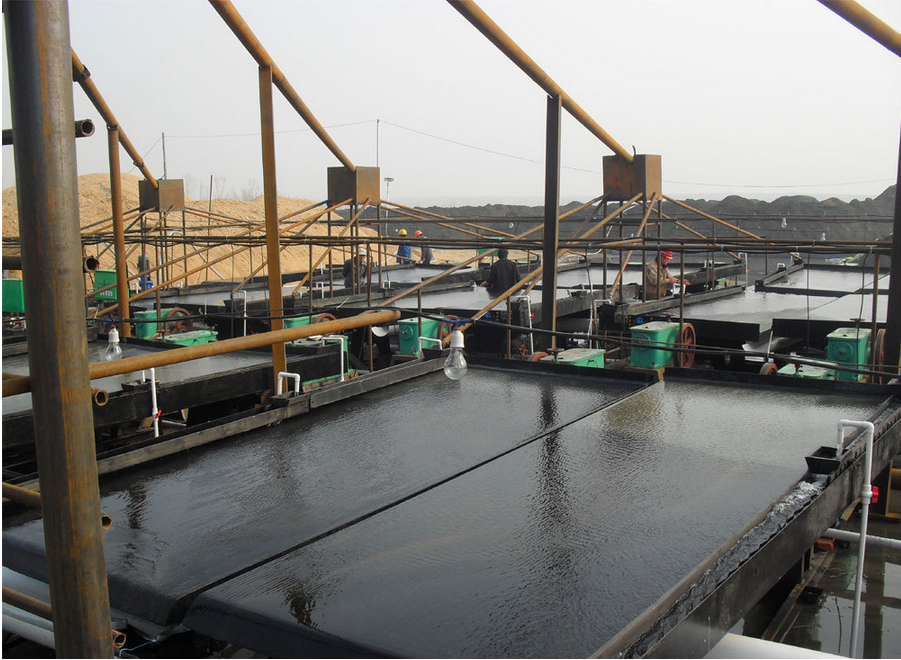

Diamond mining technology processing line

No Pics.

---About diamond

Usually Diamond price increased basis on particle size , therefore the diamond must be lossless recovery, so when you screening diamond and other minerals, Not only need use conventional ways to crush and grind small particles, but also need manually . Diamond dressing process generally includes: preparation, roughing and cleaning stages.

First, preparation stage: Before diamond dressing preparatory work including crushing, screening, washing ore, grinding, hydraulic classification. The purpose is to create good conditions for ore dressing, so that the separation operation can be carried out smoothly and achieved good results.

Second, diamond roughing: Diamond ore after crushing, screening, washing, grinding, classification and other preparatory work, it means into the benefication work. Diamond dressing is usually divided into two stages.,the first stage is coarse selection, which mainly plays an initial role in enrichment,the task is to separate a little containing diamonds of heavy minerals and a lot of without diamonds of light minerals, and finally to obtain containing diamonds of rough concentrate. There are three commonly roughing methods: panning, dressing, jig dressing and heavy medium dressing.

Third, selection: the task is further processing rough concentrates , until diamonds is picked.

Ⅰ:Preparation stage

1.Crushing

Crush is a main work before sorting diamond primary ore. In the crushing stage, on the one hand should make a full dissociation of the coarse ore, on the other hand, as far as possible to reduce broken diamond crystals, in the process of ore crushing, protection of crystals is more stringent than crushing other minerals. Crushing equipment is mainly jaw crusher, cone crusher, hydropower crusher ect.

2. screening

In diamond dressing,it is need lots of screening operations . On the one hand can timely screening out the appropriate size of ore in the crushing stage, avoid excessive crushing, reduce power consumption, improve efficiency, but also helps to protect the crystal: on the other hand can prepared for the next step. The screening equipment is screening machine, the most commonly used is vibrating screen, secondly shaker screening.

3.ore washing

Diamond placer and some primary ore containing a large amount of clay minerals in the ore, which must be removed before beneficiation . The ore washing is remove clay material processing , including two stages,is clay dispersion and make dispersed clay material separated from the granular material. The ore washing equipment used a water cannon, drum washer, tank washer and so on.

4.Grinding

Grind is continue to the crushing process, means in the mechanical equipment, by means of the medium and the ore itself impact function and grinding function, make size of ore become smaller . The main purpose of diamond ore grinding is to separate the whole or most of the small diamonds from the ore, so that recover them in the next step. In addition, according to the diamond and rocky minerals wear resistance difference, selective grinding, Most ore can be grinding to the target granularity,discarding tailings and improving efficiency. Grinding usually work in a rotating cylindrical mill. The grinding machine has ball mill, rod mill and autogenous mill,basic principle is to use the medium (or ore itself) impact ore to grinding each other.

5. Hydraulic classification

When separation small material, because screening has difficult, we often use the way of hydraulic classification. Its work principle is based on the difference in the settling velocity of the particle size (or density) in the fluid. The main equipments used in hydraulic classification are spiral classifier and hydrocyclone.

Ⅱ:Roughing stage

After crushing, screening, washing, grinding, classification and other preparatory work, Diamond ore begin to mineral processing operations

Ⅲ:Concentration stage

The task is further processing rough concentrates , until diamonds is picked. The rough selection of diamonds is usually made by gravity dressing, which is due to the low ore content of diamond ore . First,It is economically more cost-effective to use the method of gravity separation with lower production cost than other beneficiation methods. After roughing diamond ore obtained mixture of diamond and heavy minerals, the diamond content is still low. In order to obtain diamonds, the coarse concentrates must be further selected to separate the diamond from the heavy minerals and finally get separate diamond. The commonly used methods of diamond selection are manual hand sorting, X photoelectric dressing, oil dressing, magnetic separation, surface flotation, heavy liquid dressing, etc..